dredge pump on a boat factory

Latest articles

Submersible Slurry Pump

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read MoreThe slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read MoreThe basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read MoreSlurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read MoreThe FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read MoreA variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read More3. Both pumps and motors are designed separately.

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read MoreIt is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read MoreOur firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

dredge pump on a boat factory...

dredge pump on a boat factory 【dredge pump on a boat factory】

Read More

Popular articles

- Series of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

- Light-duty Slurry Pump

- Slurry Pump

- Safety

- If you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

- Slurry Pump

Latest articles

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

-

When pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

-

Submersible Slurry Pump

-

Pumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

-

What is a dredging pump?

-

Includes a large number of solids or particles.

Links

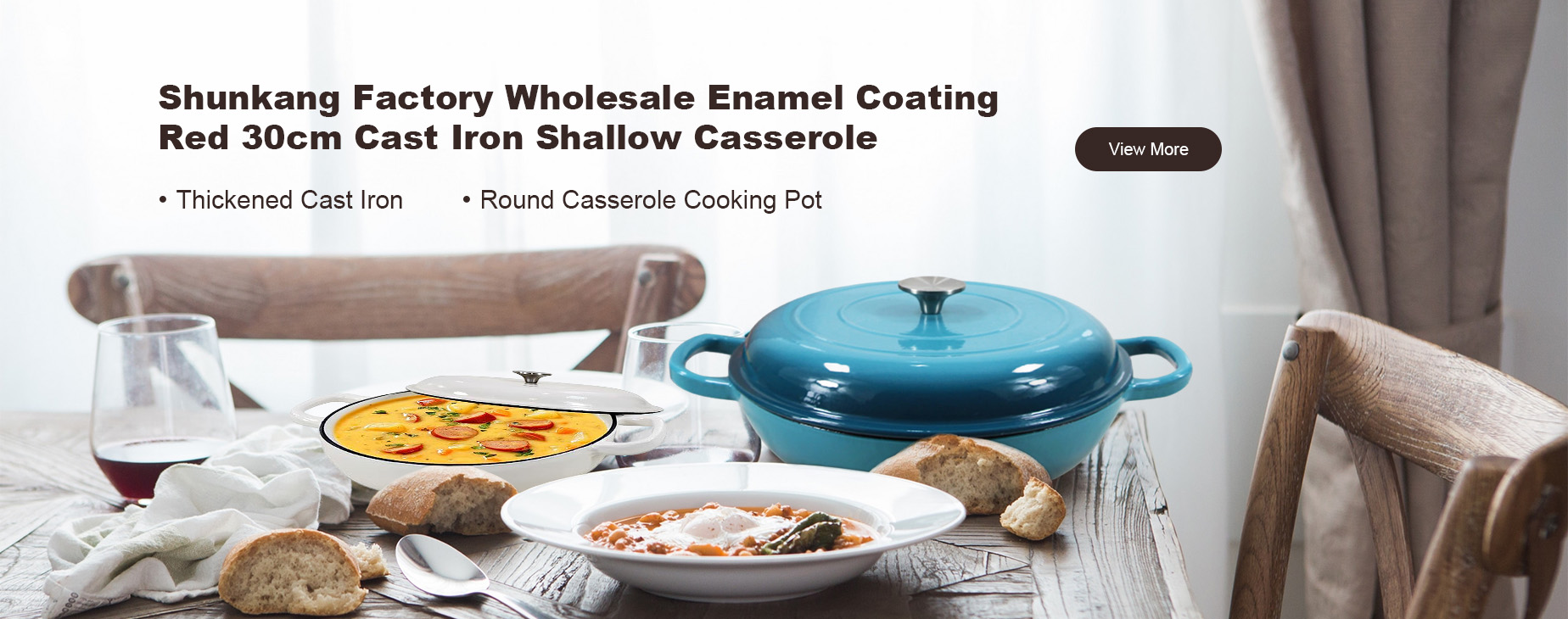

Cooking Purpose

As cast iron cookware manufacturers, we know that enameled pots are an essential cooking tool in the kitchen. However, even the highest quality enamel pots can show wear or damage.

- 6. Made In Enameled Cast Iron Cookware A newer player in the market, Made In's cookware boasts a durable enamel finish and superior heat control.

- In terms of maintenance, porcelain cookware is relatively easy to care for. It can be washed in warm, soapy water and dried with a soft cloth. However, it's important to avoid using abrasive cleaners or steel wool, as these can scratch the surface and damage the finish. With proper care, your porcelain cookware can last for years and provide you with many delicious meals to come.

- Moreover, using a black iron griddle can be a gateway to healthier cooking. Since it doesn't require artificial non-stick coatings, you can avoid potential health concerns associated with those materials breaking down over time. Plus, the natural non-stick surface formed through seasoning reduces the need for excess oils or butter during cooking, contributing to a cleaner eating experience.

- 1. Lodge Pre-Seasoned Cast Iron Grill Pan This pan is made from high-quality cast iron and comes pre-seasoned, so you can start using it right out of the box. It has a ridged surface that creates beautiful grill marks on your food and a helper handle for easy handling.

- Another benefit of cast iron is its versatility. It can be used on both stovetops and ovens, making it an all-in-one solution for a wide range of recipes. The heavy duty construction also means that the pan can withstand high temperatures without warping or losing its shape, ensuring long-lasting performance.

- Cast iron, known for its superior heat retention and distribution, has long been favored by chefs and home cooks alike. When combined with a high-quality enamel coating, it transforms into a skillet set that is both functional and fashionable. The enameled layer not only prevents rust but also eliminates the need for seasoning, making it particularly user-friendly for those new to cooking with cast iron.

- In conclusion, green enamel cast iron cookware is a versatile and sustainable choice for anyone who wants to reduce their carbon footprint while enjoying delicious, healthy meals. Its excellent heat retention, even heat distribution, and eco-friendly properties make it an ideal addition to any kitchen. So why wait? Upgrade your cookware today and start cooking with confidence and sustainability.

Best for: You can cook almost anything in these versatile pans that just get better over time. You can sear a thick piece of meat on the stovetop and then move the pan to the oven to finish. Carbon steel is good at high heat, and you can use these pans to fry eggs, fish, and make delicate sauces.

TITANIUM FRYING PANS

Enamel cookware, particularly the iconic potjie pot, offers a blend of tradition, durability, and aesthetic appeal. This article delves into the features, applications, and benefits of enamel potjie pots for sale, highlighting their timeless elegance and versatility in the kitchen.

Durable While lightweight frying pans may seem delicate, many are actually quite durable Durable While lightweight frying pans may seem delicate, many are actually quite durable

Durable While lightweight frying pans may seem delicate, many are actually quite durable Durable While lightweight frying pans may seem delicate, many are actually quite durable lightweight fry pan. Made from high-quality materials such as aluminum or stainless steel, they can withstand regular use without showing signs of wear and tear.

lightweight fry pan. Made from high-quality materials such as aluminum or stainless steel, they can withstand regular use without showing signs of wear and tear.Can You Put Non-Stick Pans in the Dishwasher?

All in all, there is a variety of cast iron cookware to suit every cooking need. Whether you're looking for a durable and versatile cookware set or specific cookware like a Dutch oven or skillet, cast iron cookware is a timeless choice that will serve your kitchen well for years to come.

Enameled cast iron cookware has become a popular choice for home cooks and professional chefs alike. This type of cookware offers the durability and heat retention of traditional cast iron, while the enamel coating provides a nonstick surface that requires no seasoning. Whether it's a pan, pot, or skillet, enamel-coated cast iron cookware is a versatile addition to any kitchen.

Versatility and Culinary Capabilities:

Here are two recommended nonstick skillets from CR’s tests.

Its ability to retain heat means that your meal stays warm long after it leaves the fire, adding a touch of comfort to your dining experience Its ability to retain heat means that your meal stays warm long after it leaves the fire, adding a touch of comfort to your dining experience

Its ability to retain heat means that your meal stays warm long after it leaves the fire, adding a touch of comfort to your dining experience Its ability to retain heat means that your meal stays warm long after it leaves the fire, adding a touch of comfort to your dining experience yellow enameled cast iron cookware.

yellow enameled cast iron cookware. Additionally, these pans are often compatible with various heat sources - gas, electric, induction, and even the campfire, providing flexibility in cooking methods Additionally, these pans are often compatible with various heat sources - gas, electric, induction, and even the campfire, providing flexibility in cooking methods

Additionally, these pans are often compatible with various heat sources - gas, electric, induction, and even the campfire, providing flexibility in cooking methods Additionally, these pans are often compatible with various heat sources - gas, electric, induction, and even the campfire, providing flexibility in cooking methods cast iron grill pan with removable handle.

cast iron grill pan with removable handle.

At its core, the Dutch oven is a heavy-duty pot typically crafted from cast iron or enameled cast iron. Its design features thick walls and a tightly fitting lid, allowing for even heat distribution and moisture retention – essential elements for achieving succulent, flavorful meals.